Laboratory chillers, or lab chillers, are used to lower temperatures and provide cooling for scientific experiments, research, and the accumulation of academic data. They function like other chillers by removing heat using a cooling vapor or compressor cycle. The chilled liquid is recirculated through a heat changer or air cooling equipment. Read More…

Our customers know they can trust us for the ultimate in quality, affordability, and flexibility. If you want a fully customized solution for your chillers, we can help! We work hard to create the best solution for each of our customers, because we know that if you are not happy, we are not happy! You can learn more about our services by visiting our website or giving us a call today!

Dimplex Thermal Solutions, based in Kalamazoo, Mich., and home of Koolant Koolers, has been manufacturing water, air, and glycol chillers since 1952. Since that time Dimplex has expanded it’s product offering to include industrial cooling for: Machine Tooling, Food Processing and Packaging, Medical Diagnostic Imaging, Laser Cutting, Manufacturing Processes and more. Dimplex is known for their...

At Tark Thermal Solutions, we position ourselves as a dedicated partner in advanced cooling technology, delivering liquid chillers that support precise temperature control across demanding applications. We design and build our systems with a focus on reliability, thermal stability, and energy efficiency, tailoring each unit so it performs consistently in environments where process accuracy...

We are ChillX Chillers, and we take pride in engineering and manufacturing reliable, high-performance chillers designed to meet the cooling needs of businesses across a wide range of industries. Our focus has always been on combining innovation, energy efficiency, and durability, which is why our chillers are trusted for everything from process cooling and manufacturing applications to...

More Lab Chiller Manufacturers

The heat collected from the cooling process is released into the environment through a set of fans or a cooling tower.

Lab chillers vary from traditional chillers due to the nature of their use. In most cases, they are mobile with wheels or small enough to be carried or set on a counter. In manufacturing, lab chillers are used to test the limitations of a product, part, or component such that engineers can make adjustments to improve longevity and durability. In educational settings, research facilities, and the chemical industries, lab chillers are used for research, scientific experimentation, and empirical data collection.

Types of Laboratory Chillers

There is an endless list of the different types of lab chillers due to their many uses. For laboratory use, lab chillers are considered an instrument designed to provide the necessary conditions for experimentation and research. They cool MRI machines, linear accelerators, CT scanners, radiation therapy equipment, and blood cooling systems. In most instances, they must be customized to fit their applications.

Lab chillers are classified by their compressor type since their other elements are identical. The purpose of the compressor is to take the refrigerant gas and place it under pressure sufficient enough to release the heat collected in the condenser.

The basic components of all chillers are the condenser, expansion valve, evaporator, power supply, controller, and compressor. These parts are common to all chillers, with the compressor being one of the central and most important parts. One exception to the generalization of compressor components is the water box found only on water-cooled chillers, which collects water from the evaporator and condenser.

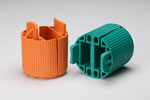

Screw Compressor Lab Chiller

A screw chiller compressor has two helical screws or male and female rotors that intermesh to compress refrigerant gasses. For a screw compressor to function properly, the rotors must mesh at a very high tolerance to supply the necessary pressure. A screw compressor operates according to a positive displacement mechanism where the concave cavity of the female rotor meshes perfectly with the convex blades of the male rotor.

Reciprocating Lab Chiller Compressors

Reciprocating lab chiller compressors compress refrigerant gasses using the stroke of a piston. The refrigerant gas is drawn into the piston cylinder through the inlet valve by the piston moving backward, which lowers the pressure in the cylinder to below the atmospheric pressure. During the backward motion of the piston, the cylinder becomes pressurized, and the inlet valve closes. With the forward motion of the piston, the pressure on the refrigerant gasses increases and forces the outlet valve to open and release the pressurized refrigerant into the condenser.

Centrifugal Compressor Lab Chillers

Centrifugal compressors for lab chillers use centrifugal force to increase the pressure and temperature of refrigerant gasses. In a centrifugal compressor, gasses are compressed by an impeller's radial acceleration and the compressor's tightly sealed casing. As the gasses pass through the rapidly rotating impeller, they are exposed to centrifugal force. The velocity and speed of the impeller increase the pressure on the gasses.

A diffuser, connected to the compressor chamber, guides and moves the gasses out of the compressor to the condenser. In the diffuser, the velocity decreases, which increases the pressure in the gasses. The impeller increases the pressure by 65%, while the diffuser increases it by 35%.

Absorption Lab Chiller

An absorption lab chiller is unlike lab chillers that depend on a compressor to pressurize refrigerant gasses. In place of a compressor, absorption chillers have an absorbent into which the vapors of the refrigerant are dissolved. The idea behind their operation is to separate and combine the refrigerant and the absorbent to create cooling. In the first phase of the process, an ammonia-water solution acts as the refrigerant, while in the latter phase, lithium bromide is the absorbent and water is the refrigerant.

The elements of an absorption chiller do not include a compressor but are composed of a generator, condenser, evaporator, and absorber. In the evaporator, the heat from the process is absorbed, and the refrigerant leaves as ammonia vapor. In the absorber, the vapor is exposed to an ammonia-water solution that becomes a strong solution at high pressure. From the absorber, collected heat is released into the atmosphere.

Benefits of Lab Chillers

-

Accuracy – Lab chillers ensure the accuracy of temperatures and eliminate the potential negative effects of environmental factors.

-

Sustainability – Previously, water was used to cool portions of research and experiments, which was costly and wasteful. Lab chillers have been implemented as a cost-saving and eco-friendly replacement.

-

Cost Savings – Cost savings is the main reason that lab chillers have become so essential.

-

Convenience – Cooling methods using water, ice, dry ice, or liquid nitrogen required much effort that was eliminated by lab chillers.

-

Safety – Chemicals can react adversely if placed in conditions where the temperature is not precision-controlled.

Selecting the Correct Lab Chiller Supplier

To ensure the most productive outcome when purchasing a lab chiller from a lab chiller company, it is important to compare several companies using our directory of lab chiller suppliers. Each lab chiller company has a business profile page highlighting their areas of expertise and capabilities, along with a contact form to directly communicate with them for more information or request a quote. Review each lab chiller company website using our proprietary website previewer for a better understanding of what each business specializes in. Then, use our simple RFQ form to contact multiple lab chiller businesses with the same form.

Boilers

Boilers Chillers

Chillers Cooling Towers

Cooling Towers Furnaces

Furnaces Heat Exchangers

Heat Exchangers Heat Transfer Equipment

Heat Transfer Equipment Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services