A variety of medical procedures require the use of chilling mechanisms. Many surgeries and procedures require removing heat from body parts or lowering a person’s body temperature, like laser surgery, hair and tattoo removal, vein treatments and laser eye surgery. Orthopedic rehabilitation and hypothermia procedures also use custom medical chillers for cooling down thermal pads after use. Read More…

Our customers know they can trust us for the ultimate in quality, affordability, and flexibility. If you want a fully customized solution for your chillers, we can help! We work hard to create the best solution for each of our customers, because we know that if you are not happy, we are not happy! You can learn more about our services by visiting our website or giving us a call today!

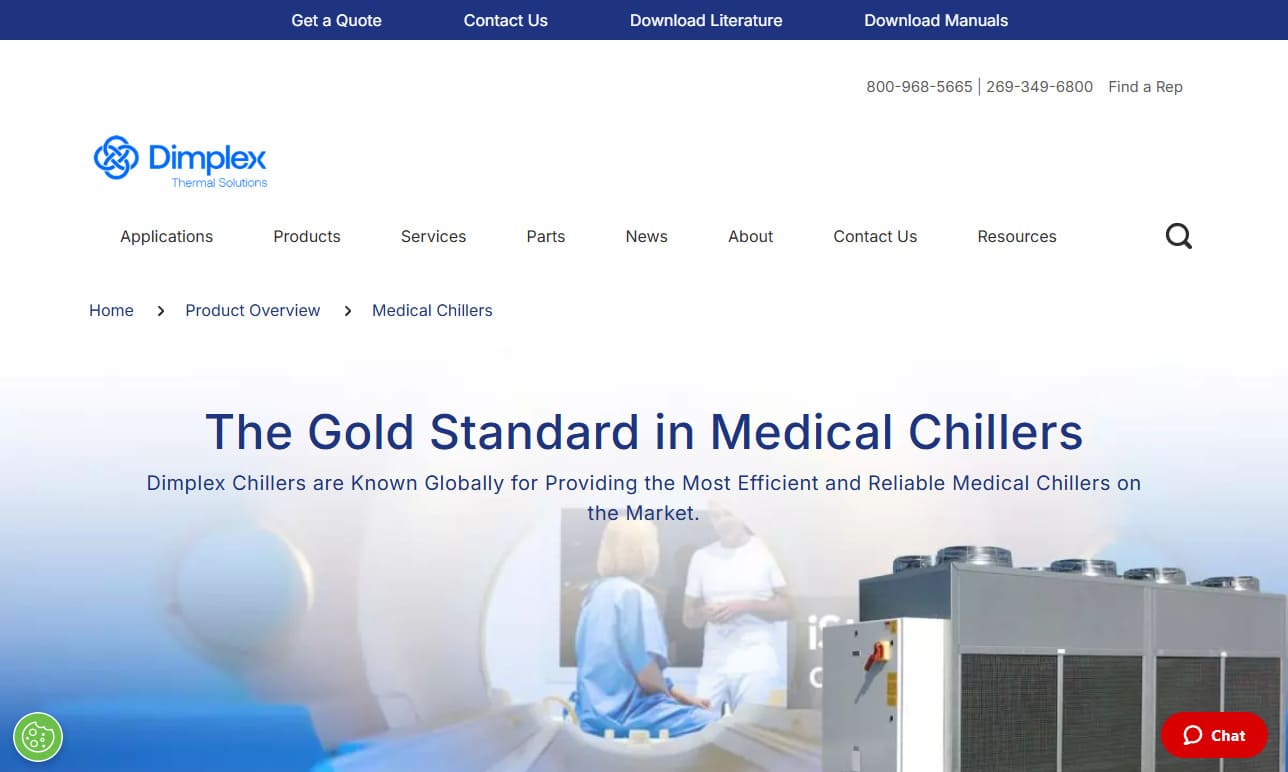

Dimplex Thermal Solutions, based in Kalamazoo, Mich., and home of Koolant Koolers, has been manufacturing water, air, and glycol chillers since 1952. Since that time Dimplex has expanded it’s product offering to include industrial cooling for: Machine Tooling, Food Processing and Packaging, Medical Diagnostic Imaging, Laser Cutting, Manufacturing Processes and more. Dimplex is known for their...

At Tark Thermal Solutions, we position ourselves as a dedicated partner in advanced cooling technology, delivering liquid chillers that support precise temperature control across demanding applications. We design and build our systems with a focus on reliability, thermal stability, and energy efficiency, tailoring each unit so it performs consistently in environments where process accuracy...

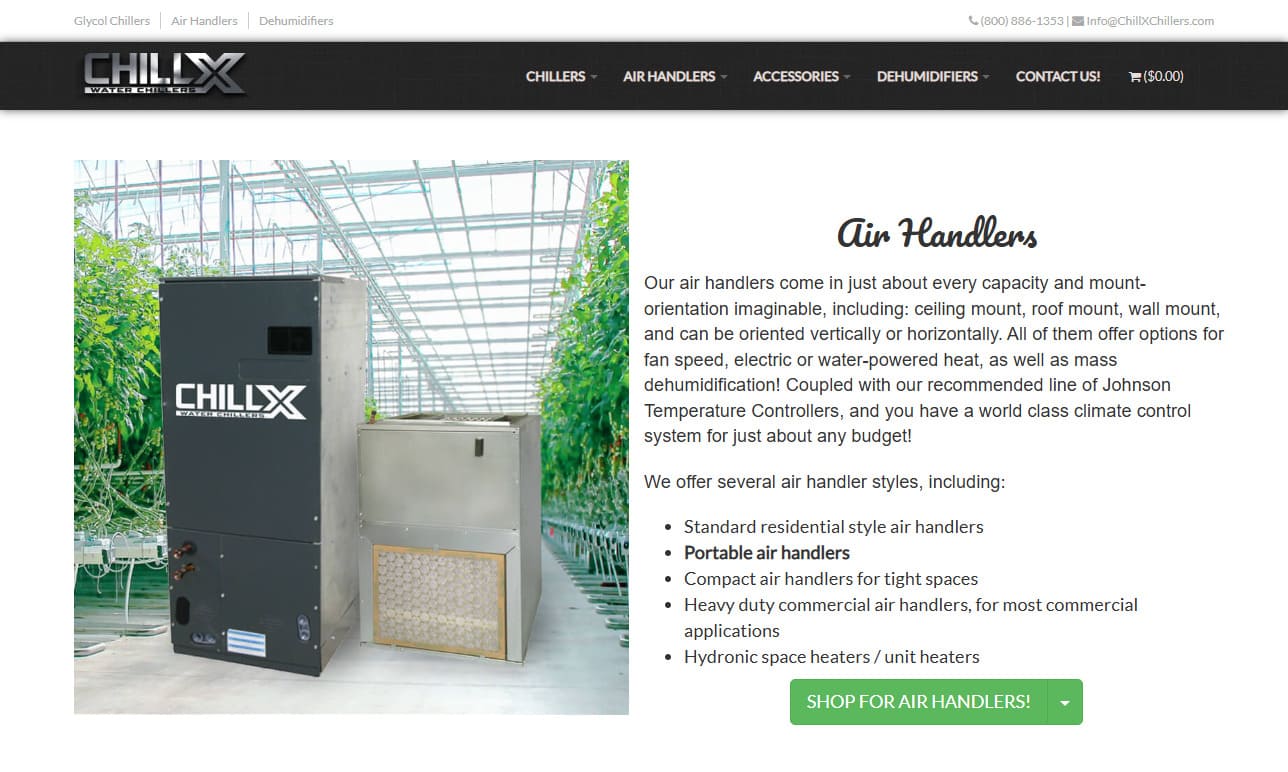

We are ChillX Chillers, and we take pride in engineering and manufacturing reliable, high-performance chillers designed to meet the cooling needs of businesses across a wide range of industries. Our focus has always been on combining innovation, energy efficiency, and durability, which is why our chillers are trusted for everything from process cooling and manufacturing applications to...

More Medical Chiller Manufacturers

Medical machines like MRIs, PET and CAT scans, linear accelerators, lasers and x-ray machines generate a large amount of heat, and must quickly cool down in order to work properly for an extended period of time. Large chillers are used to better control the temperature after one of these machines is used, to prevent overheating.

One of the most common medical chiller applications takes place in laboratory testing. Often, blood samples undergo testing and must be cooled down to a certain temperature. They are placed in smaller chillers to obtain the desired temperature.

Medical chillers may be small cabinets that fit blood samples and small instruments, or large enough to cool down an MRI machine. Hospitals use large, central chillers that are in integral part of a room and combine many heat exchangers and external cooling towers. They are dedicated-process chillers, meaning they operate year-round and are designed to provide specific, capacity-matched cooling protection and proper temperature and water flow, since they are used so often.

Their housing is insulated and generally constructed of a reinforced metal like aluminum or stainless steel. Other components may include a thermoelectric cooling engine, liquid reservoir, pump, power supply, temperature controls, an enclosure and wiring. They often offer higher pressure pumping, temperature stability and microprocessor controls.

Medical chillers cool temperatures by passing a refrigerant gas through a heat exchanger while a liquid flows in the other direction on the opposite side. The gas absorbs the heat lost by the liquid. The air is cooled, and moved by a system of fans around the facility or within the cabinet. The liquid is then transformed into a very cold mist.

Boilers

Boilers Chillers

Chillers Cooling Towers

Cooling Towers Furnaces

Furnaces Heat Exchangers

Heat Exchangers Heat Transfer Equipment

Heat Transfer Equipment Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services